Safe Standards

CERTIFIED STRENGTH: To provide the appropriate level of protection, the products are tested to comply with the latest industry standards.

The various certification tests carried out in independent laboratories for burglary or fire protection are conducted by experienced operators armed with plans of the product and a whole range of tools.

FOR BURGLARY PROTECTION, safes and vaults are awarded grades:

- For security cabinets, there are Grades S1 and S2 (EN 11450).

- For safes, vaults and vault doors, they are rated from Grade 0 to Grade XIII (EN 1143-1) and from class TL-15 to class 3 (UL 687 and UL 608).

- High security locks are graded according to EN 1300 or UL 1034 and security doors sets, windows and partitions are ranked from RC1 to RC6 (EN 1127).

During the certification process, door panels of the products, bolt works, locks and handles are tested. The certification tests include an attack program that is devised so that various break-in attempts can be made using a selection of tools. A correlation between tool type and the time for which each one is used can be used to obtain a resistance score (resistance unit). The higher the score, the higher the level of resistance. Based on the results obtained, the safe is given a classification and then listed in a resistance grade.

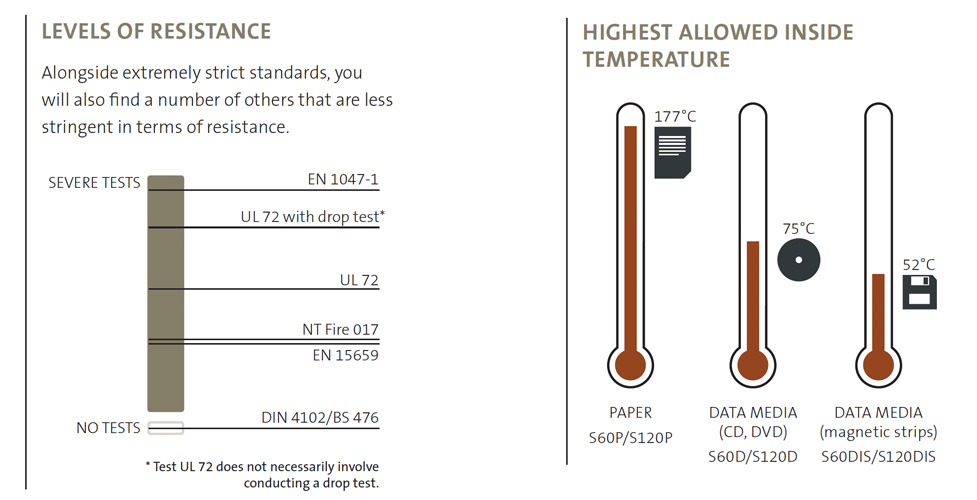

FOR FIRE PROTECTION, these standards vary according to whether you want to protect paper documents, digital media or other highly sensitive objects. This is because the temperature at which data media (e.g. 52°C) and documents (e.g. 177°C) deteriorate differs according to the item protected:

- In order to fully protect data media, industry standards indicate that products should carry ECB•S EN 1047-1, UL 72 Class 125 or NT Fire 017 60/120 DIS. The ECB•S and UL tests monitor the internal temperature of the data cabinet until it has completely cooled down during the “soakout” period. Assessing products during this period is essential, since internal temperatures can peak up to six to eight hours after a fire has been extinguished. Such tests ensure that all products are comprehensively tested and, upon passing, will fully protect your data media for the specific time period stated.

- For document protection, all products must have an appropriate industry standard 30- or 60-minute paper certificate.

UL72-Class 350, ECB•S EN 1047-1, EN 15659 or NT Fire 017 are acceptable standards for paper document protection.

STANDARDS IN BRIEF

| STANDARDS | Temperature Test | Drop Test | Paper | Data Media | Cooling |

| EN 1047-1 | 1090C | 9.15 metres |

S 60P (60min) |

S 60DIS (60 min) S 120DIS (120) |

incl. the cooling period |

| UL 72 | 1000C | 9.15 metres* | Class 350 (1/2,12 hours) | Class 125 (1/, 1,2 hours) | incl. the cooling period |

| EN 15659 | 850C | no | LFS 30P (30 min) LFS 60P (60 min) |

no application | not tested |

| NT FIRE 017 | 927C | no | 60 paper (60 min) 120 paper (120 min) |

60 diskettes (60 min) 120 diskettes (60 min) |

not tested |

| DIN 4102/BS 476 | not tested | not tested | not tested | not tested | not tested |

*Test UL 72 does not necessarily involve conducting a drop test.